- Home /

- Tooling /

- CK Boring System /

- BIG Kaiser RW Rough Boring Heads /

- RW Rough Boring Heads

- 3D Printing Additive MFG

- CNC Machines in Stock

- Industrial Lubricants

- Machine Accessories

- Metrology

-

Tooling

- Broaching

- CK Boring System

- Counterbores

- Countersinks

-

Drills

-

Endmills

- Grooving & Part Off

-

Milling Bodies & Inserts

- BIG Fullcut 90 Degree 2 Edge Insert

- Korloy RM3 90 Degree 3 Edge Insert

- Sumitomo DFC 90 Degree 6 Edge Insert

- Sumitomo MSX High Feed Insert

- Sumitomo RSX Button Insert

- Sumitomo WAX Aluminium 2 Corner Insert

- Sumitomo WEX 90 Degree 2 Edge Insert

- Sumitomo WEZ 90 Degree 2 Edge Insert

- Sumitomo WFX 90 Degree 4 Edge Insert

- Sumitomo WRCX Button Insert

-

Milling Holders

- Reamers

-

Taps

- Threading

- Threadmills

-

Turning Holders

-

Turning Inserts

-

Workholding

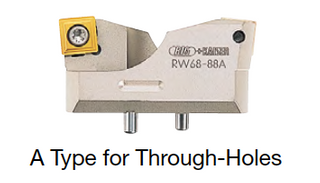

RW Rough Boring Heads

BIG KAISER RW - 25 ~ 150mm Rough Boring Heads

BIG RW twin cutter boring heads are designed for heavy duty rough boring and semifinishing operations. Their compact, sturdy design and postive geometry allow almost chatter-free operation even in interrupted cuts and high cutting speeds. Twin cutter boring heads can outperform single cutter finishing heads by a factor of up to 4 times. Large stock allowances and high feed rates permit high production while assuring optimum bore roundness and location, two important quality features for todays tighter control of part geometry. In many cases, these tools can eliminate the need for semi-finishing cuts due to the superb balance of cutting forces, even under the most severe casting core shift.

BIG RW tool use ISO standard inserts with postive cutting geometry for reduced cutting forces. The top clamp free mounting of the inserts and wide open chip spaces between the insert holders allows perfect chip formation and evacuation. Different grades and geometries of carbide and silicon nitride inserts are available to optimise all application criteria.

Features & Benefits:

* Axial adjustment mechanism achieves "perfect balance cutting"

* The "step cutting method" can reduce the number of passes in the application with a large stock allowance